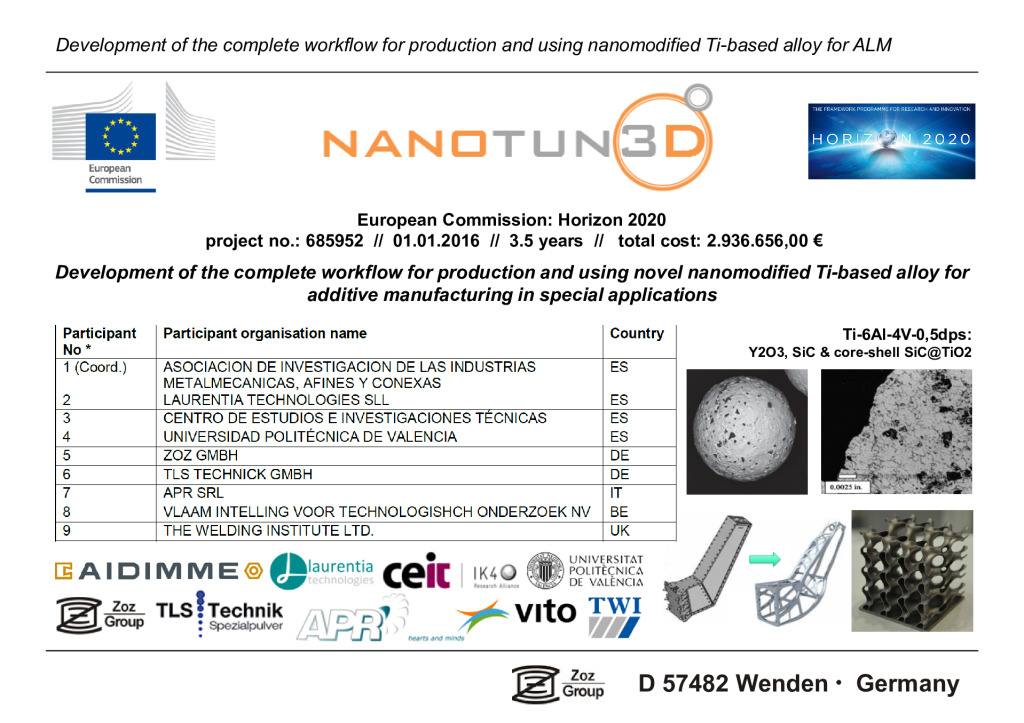

NANONTUN3D will take advantage of the possibilities of Additive Manufacturing (AM) together with the development of a specially tailored Ti- based nano-additived material to achieve dramatic improvements in structural parts of aero, space, mobility, and equipment sectors, reaching expected savings between 40% and 50% of material in critical applications. Inherent benefits of AM will be kept (decrease in throughput times, tool-less production, high buy-to–fly-run ratios, etc.).

By adding nano-particles (NPs) to metal matrixes, the whole life cycle of the NANOTUN3D material has been designed with AM processability in mind: safety and handling issues, processing in well-known AM technologies, postprocessing and eventual certification issues are dealt with, and innovative core-shell treatment of the NPs that suits the Ti matrix and produces Ti64-like powder ready to be AM processed. A whole Health, Safety and Environmental (HSE) management system will also be developed, as well as all the protocols to start qualification/certification of material and process.

Partner:

NANOTUN3D is also a well balanced consortium, with 7 out of 9 partners leading WPs, and the rest having relevant participation in the workplan. Most of the partners know each other from former projects in the last 3 years, which aims at a good coordination, too.

The structure of the NANOTUN3D consortium answers to 4 key ideas in H2020:

Technology complementarity and value chain coverage: The two topic disciplines (nanotechnology and AM) are represented in the consortium -respectively LAU, UPV, VITO, and AIM and TWI. The intermediate state (powder) is dealt with by CEI, TLS and ZOZ. APR represents the transformation of the processed material in a functional part.

The life cycle of the material to be developed is also fully covered by the partners: nanoparticle modification (LAU and UPV), powder integration, consolidation and production (TLS, ZOZ and CEI), AM process (AIM, TWI), postprocessing (APR), and safety management (VITO).

TRL representation and execution: NANOTUN3D TRLs are represented in the partners’ roles:

• TRL4 (Technology validation in laboratory): UPV, CEI, AIM, TWI, VITO

• TRL5 (validation in relevant environment): LAU, TLS, ZOZ, APR, as well as some tasks from CEI, AIM, TWI and VITO.

Exploitation oriented: Technology, knowledge, technical servicing and production can be directly exploited by the partners either internally or as future market opportunities.