Crushing, mixing, dispersing, homogenizing and passivating

at low to medium kinetic – describes the utilization of roller mills. Years ago, such requirement also arose in Zoz laboratory operations. The market provided these comparatively simple devices, but at appropriate appearance and flexibility for laboratory use. The Zoz RM1 roller mill was born, followed by the RM20 and various special types, e.g. for direct installation in a glovebox or versions with protective hood and soundbox. Processing container spectrum under constant expansion towards customer orientation.

| Rollermill RM1 | Rollermill RM1s | Rollermill RM1-GB |

|

|

|

| Rollermill RM20, RM20l | Processing-Container | |

|

|

The Rollermill is a variation of milling devices, where simple handling, suitability of almost each circular vessels and low investment costs are required.

The typical feature of the Roller-Mill RM1 is the direct drive inside the rolls. Because (drive-) protections are not necessary, the design is extremely compact.

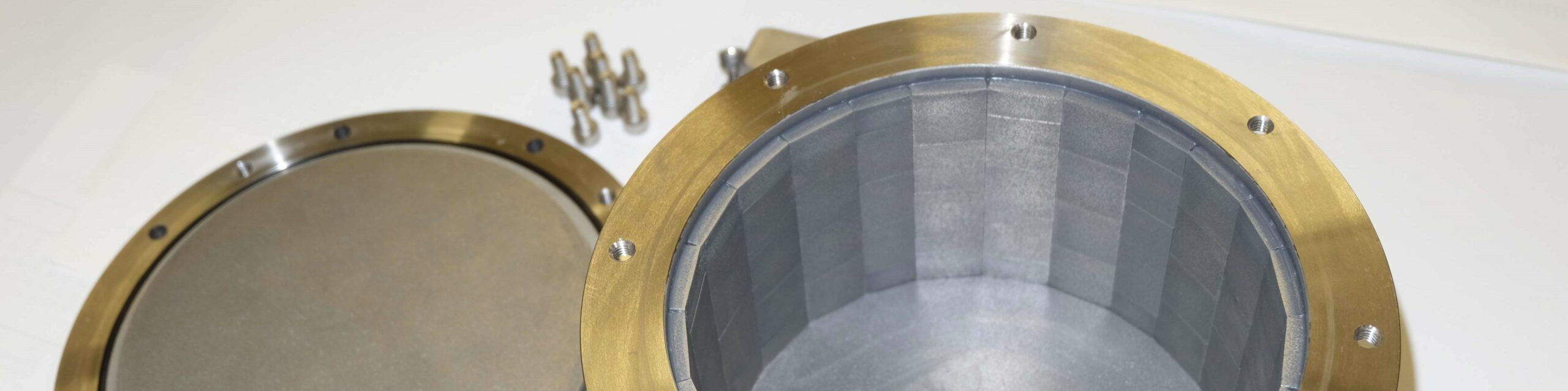

Rollermills are used as laboratory equipment for grinding, mixing, dispersing and homogenizing. Processing-/grinding containers in stainless- or wear-resistible steel, glass, (transparental) plastics, porzelain, several ceramic (linings), coatings (e.b. rubber, hard metal, CVD etc.).