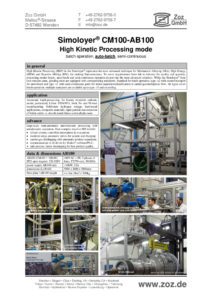

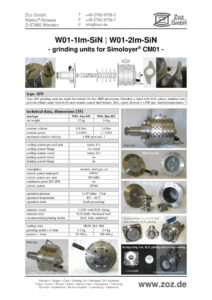

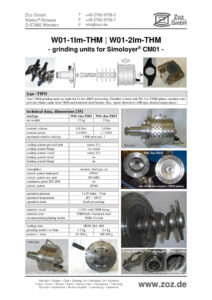

High Kinetic Processing (HKP) in the Simoloyer® represents the most advanced technique for Mechanical Alloying (MA), High Energy (HEM) and Reactive Milling (RM) for making Nanostructures. Simoloyer® base unit remains the same in batch–, auto–batch and semi–continuous operation while different grinding units are equipped with corresponding ports. Standard for batch operation, type –s2 with 2nd mainport for auto–batch and type –s1 with semi–continuous ports for insitu separation/classification at carrier–gas/multiphase flow. All types cover batch operation, multiple mainports available up to type –s5 and exceeding. Grinding units from steel to ceramic Si3N4 to WC–Co.

|

|

|

Simoloyer® (flyer general) |

||

|

||

Simoloyer® scale CM01- CM900 |

||

|

|

|

|

|

|

| Simoloyer® CM100-s1 |

Simoloyer® CM400 |

|

|

|

|

batch, auto-batch & semi-continuous operation |

||

|

|

|

|

|

|

|

|

|

|

|

|

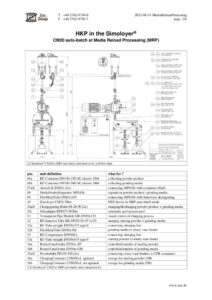

| Media Reload Processing (MRP) |

||

|

|

|

|

|

|

| video RotaryVaneFeeder pilot |

| Media Reload Processing (MRP) for SMART (PM2020*) | ||

|

|

|

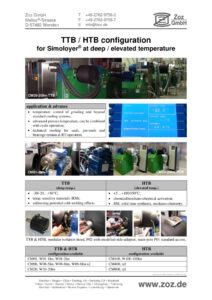

extensions |

||

|

|

|

|

|

|

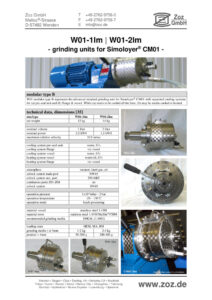

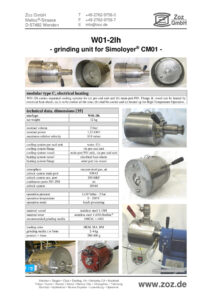

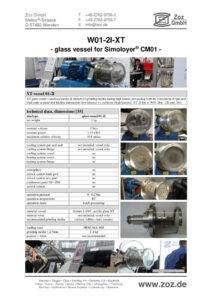

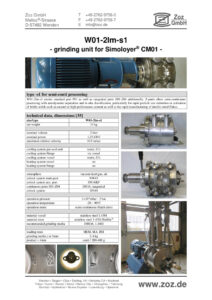

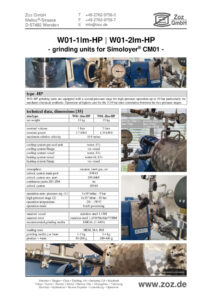

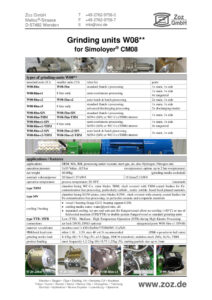

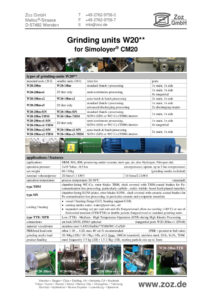

grinding units |

||

|

|

|

|

|

|

|

|

|

|

|

|

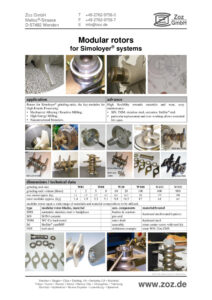

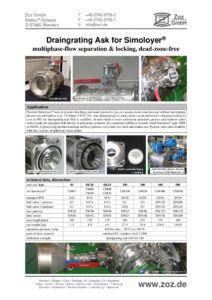

rotors & draingratings

|

||

|

|

|

| requirements for set-up & operation | ||

|

|

|

scale-up vs. heat exchange |

||

|

|

|

Software